Marist’s Maker Lab Facilitates 3D Research

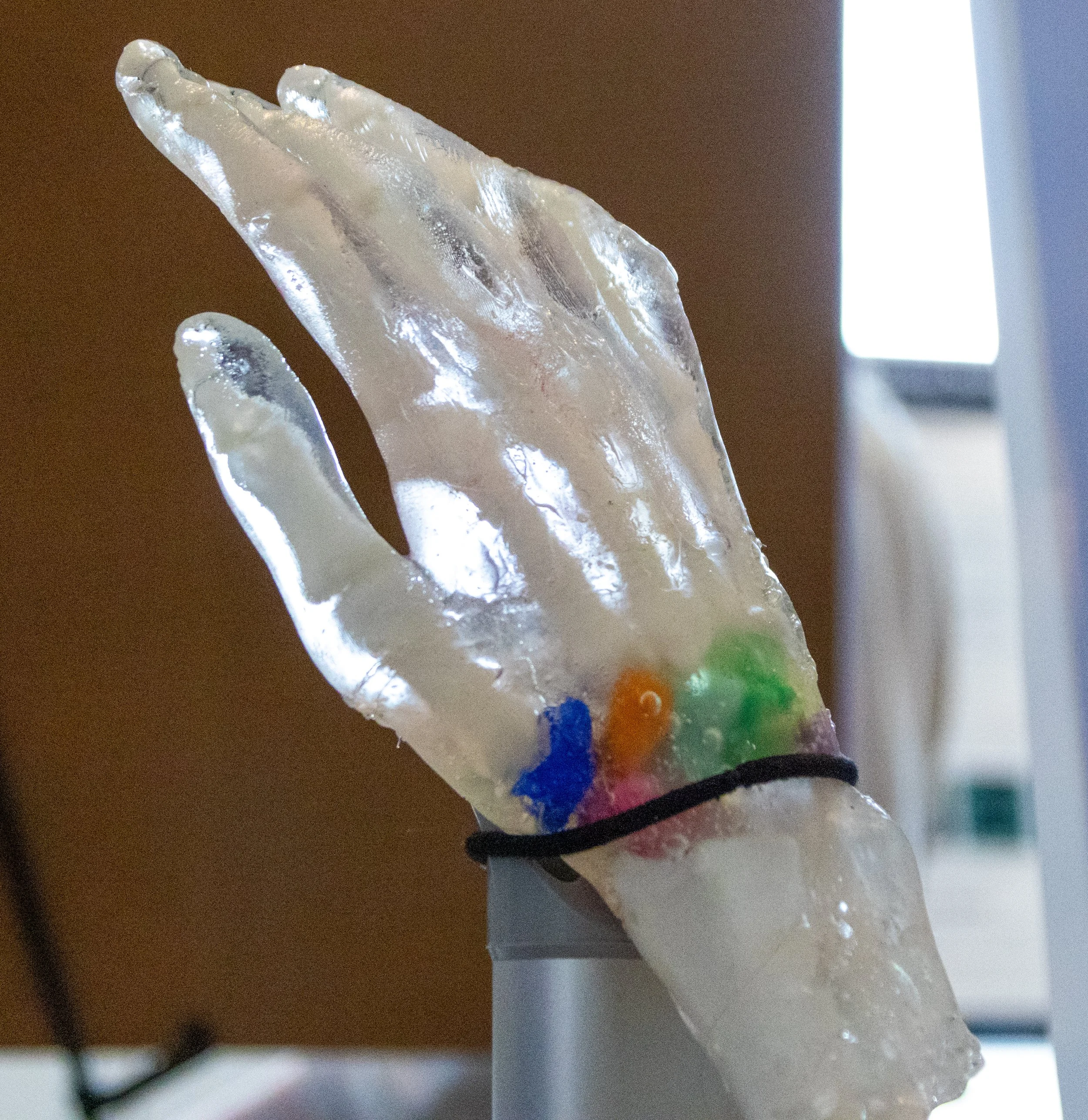

A close-up detail image of the 3D printed hand on April 17, where details of the bones and ligaments can be seen through the transparent model. Photo by Emily Sumner '25

Brianna Balzan ‘24 3D printed bones of her own hand with the help of resources at the college.

Hidden behind the grandeur of the Steel Plant Cafe lies Marist College’s Maker Lab. Its 3D printing machines have been put to work as Brianna Balzan ‘24 has taken advantage of this technology to create replicas of her own hand, a project which she presented at the Celebration of Undergraduate Research, Scholarship and Creative Activity on April 17.

The project’s genesis was formed by Dr. Christina Fojas, assistant professor in the School of Science, as a way for students to locate the eight carpal bones in the hand. As the Gross Anatomy Lab’s Director, she sought a solution, which came when Balzan happened to be in her undergraduate anatomy class and working as a Maker Lab technician.

Dr. Fojas, aware of Balzan’s prior experience in high school and her access to top-of-the-line technology, swung back around later with the project, knowing Balzan was the perfect candidate to take it on. Since fall 2023, the two have merged two drastically different academic disciplines here at Marist to create a project that has never been done before.

“The Maker Lab’s location makes it seem like it’s just for fashion students, but it’s a space for all disciplines at Marist,” said Maker Lab manager Ais Oisín, who played a critical role as project advocate and as the line of communication between the Maker Lab and Fojas.

Both Oisín and Fojas hope that this collaboration between the School of Science and the School of Communication and the Arts will foster more research and more students who are willing to collaborate with faculty on projects — especially by using the Maker Lab, which is home to 3D printers, a photo studio and more.

The process involved a lot of trial and error because the model is the first of its kind. With no examples to go off of, Balzan struggled to get the model right and experienced failed attempts with a Vacuform technology trial. Both Fojas and Balzan dealt with long nights resolving issues with the gelatin-based substance surrounding the model, and the process was messy and imperfect.

Balzan and Fojas worked tirelessly alongside the Doctor of Physical Therapy students to research and try out each new model. Each failed trial brought them closer to the light at the end of the tunnel. For the current model presented at CURSCA, Balzan used PLA 3D printer filaments for the bones and clear wax to hold them together. The clarity, flexibility and elasticity of the gelatin allows the model to be squeezed, letting its user make sense of the jumble of carpal bones in the hand.

The current model and process were on display at CURSCA, though the project is still in progress, and this is not the final product. It has highlighted Marist’s Maker Lab and how it can be an asset to research at Marist.

Research is an integral component of graduate applications for many science majors — an opportunity that, so far, has been limited. “We’re trying to increase the number of faculty available to mentor students, and it starts with faculty engaging students in the classroom,” said Fojas.

Oisin shared this sentiment, saying that they hope to see a student continue to work with the School of Science alongside the Maker Lab to fill spaces where information is missing. Balzan’s project is an example to the rest of the School of Science as to what can be accomplished when taking advantage of Marist’s resources.